When I first started working on surface preparation jobs, I quickly learned one lesson: using the wrong equipment doesn't just waste time — it can ruin the entire project. Over the years, I’ve seen too many contractors try to cut corners, only to pay for it later with callbacks and unhappy clients.

Shot blasters are great for tough cleaning and fast coating removal, while concrete grinders deliver that smooth, polished finish everyone loves. The trick is knowing which one fits your project goals.

Here’s how I break it down whenever I help clients choose.

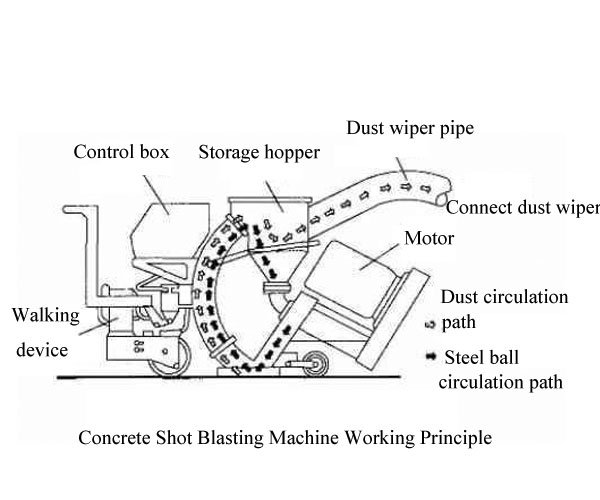

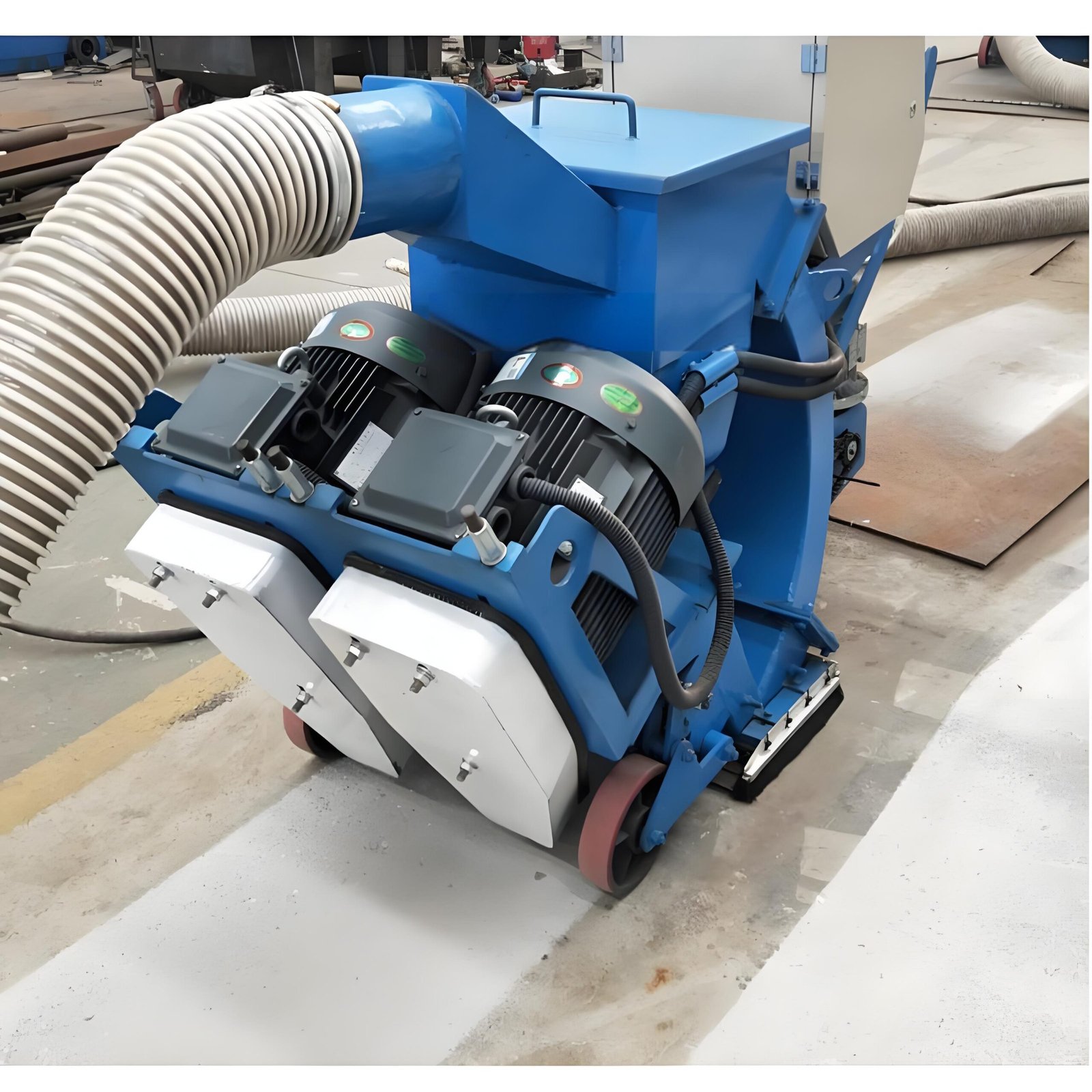

What Exactly is a Shot Blaster?

A shot blaster uses high-speed steel beads or similar media to hammer away at the surface. Think of it like a mini hammering army attacking dirt, coatings, and old paint layers. It’s loud, aggressive, and extremely efficient.

Shot blasters are designed to clean and texture large surfaces fast, making them perfect for heavy-duty prep work.

Where They Shine

I’ve used shot blasters for everything from warehouse floors to ship deck renovations. They excel at:

- Stripping thick epoxy or old coatings

- Cleaning concrete or steel surfaces before recoating

- Creating a rough profile that helps new coatings bond better

| Feature | Benefit |

|---|---|

| High efficiency | Clean large areas quickly. |

| Strong profile | Great surface texture for adhesion. |

| Dust control | Integrated collection reduces mess. |

But keep in mind, shot blasters leave a more aggressive finish. If you need a perfectly smooth surface, they might not be the best choice.

What About Concrete Grinders?

Concrete grinders use diamond tools to shave down the surface layer by layer. I still remember the first polished concrete showroom floor I worked on — after seeing the final gloss, I understood why designers love grinders.

Grinders are built for smoothness and precision.

Ideal Use Cases

- Polishing decorative concrete floors in retail stores or showrooms

- Preparing garage or residential floors for sealers

- Fixing minor surface imperfections before final coating

| Feature | Benefit |

|---|---|

| Smooth finish | Great for high-end or decorative jobs. |

| Flexible use | Can work dry or wet. |

| Precision | Fixes small uneven spots. |

On the flip side, grinders are slower when it comes to large-scale coating removal and aren’t as effective for creating heavy profiles.

Shot Blaster vs. Concrete Grinder: Core Differences

If you’re still unsure, here’s a side-by-side based on what I’ve seen in the field:

| Aspect | Shot Blaster | Concrete Grinder |

|---|---|---|

| Speed | Faster for large areas | Slower but more precise |

| Surface Profile | Rougher, textured | Smooth, polished |

| Cleanup | Better dust control | Needs more debris management |

| Best Use | Heavy-duty prep, large floors | Decorative or fine finishes |

When to Choose a Shot Blaster

I recommend a shot blaster when:

- You need to remove thick coatings fast.

- You’re prepping large areas like warehouses or industrial floors.

- You need a rough profile to improve coating adhesion.

I’ve watched teams finish 1,000 m² in a single day with a good shot blaster — something that would take days with a grinder.

When to Choose a Concrete Grinder

A grinder makes sense if:

- Your main goal is a smooth, glossy finish.

- You’re prepping for decorative coatings or sealers.

- You’re fixing small surface defects or leveling out slight bumps.

In high-end retail or residential projects, I’ve always trusted grinders to get that "showroom floor" look.

The Rise of Multi-Purpose Systems

Lately, I’ve seen more clients ask about hybrid machines that can switch between blasting, grinding, and even scarifying. They might not be perfect at each task individually, but for contractors juggling different jobs, these machines save space and budget.

| Advantage | Explanation |

|---|---|

| Versatility | Handle multiple tasks with one setup. |

| Time-saving | Switch modes without equipment swaps. |

| Cost-effective | Avoid buying separate machines. |

Conclusion

Choosing between a shot blaster and a concrete grinder isn’t just a technical decision — it’s a business decision. A shot blaster is your go-to when you want raw power and speed on big, rough jobs. A concrete grinder is your best bet when appearance and smoothness matter most.

The best advice I can give: start with your final surface goal, then choose the tool that gets you there most reliably and profitably.